Bamka jilicsan ee tspr

TSPR caagga caagga ahBamka jilicsan oo jilicsansWaxaa lagu heli karaa dherer kala duwan oo heer sare ah oo ku habboon qoto dheer oo ku-dhajinta, oo loogu talagalay xawaaraha qarka sare ama meesha xawaaraha sare ee xadidan oo lagu dhejin karo dhererka hoose si loo dheereeyo mootada ilaa 2 mitir. Bamgareynta ayaa la ilaaliyaa xitaa marka let-ka ugu sareeya ee aan lagu qasbin, sidaasna u siinta heerka dareeraha in lagu yareeyo midig hoose ama hoose ee tuubbada fidinta nuujinta. Qaybaha qoyan ee TSPR-ka bamka tooska ah ayaa lagu isweydaarsan karaa iyada oo la adeegsanayo bambooyinka adag ee SP SEPEN.

Astaamaha naqshadeynta

√ Qaadashada Golaha - Garoomada, qarka iyo guryaha ayaa si deeqsinimo leh u dhiganta si looga fogaado dhibaatooyinka la xiriira hawlgalka shaashadda danta sare ee aagagga ugu horreeya ee xawaaraha.

Goluhu waa dulucda dufan oo lagu xiray shahyrinths; Sare sare waa dufanku oo la nadiifiyaa oo uu ilaaliyaa qulqulka qaaska ah. Dhamaadka kore ama wadista gawaarida waa nooc isbarbar dhigaya Nidaamkan waxqabadka sare iyo xarkaha adag ayaa baabi'iya baahida loo qabo in la qaado hoos udhaca.

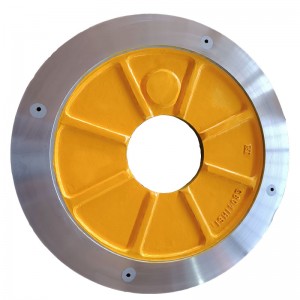

√ Golaha Saxarka - Gabi ahaanba ka been abuur bir khafiif ah. Qaabka TSPR waa la daboolay Elastomer.

√ Casing - wuxuu leeyahay lifaaq fudud oo ku xirnaanshaha salka santuuqa. Waxaa laga soo saaray xidhashada u adkaysta TSP iyo ka soo baxa Etastomer ee loogu talagalay TSPR.

√ Jidhle - labalaab sameeyeyaal labanlaab ah (gelitaan sare iyo hoose) oo ay ku khasbeyso xamuul aad u hooseeya oo aad u culus tahay caabbinta ugu badan ee caabbinta ugu badan ee caabbinta ugu badan iyo wax ka qabashada cunnooyinka adag. Xiro alloy cakiran, polyurethane iyo kuwa aan caadiga ahayn ee qalabka elastomer-ka ee loo yaqaan 'Elastomer' waa isweydaarsi. Dambiilayaashu waxaa lagu hagaajiyaa faleebadaha dhexdeeda inta lagu gudajiro inta lagu gudajiro shilalka dibedda ee ka hooseeya cagaha guryaha. Ma jiro wax istcimaal dheeraad ah oo lama huraan ah.

√ Strainer Strainer-ka - Meel bir-bir ah; Snap-on erastomer ama polyurethane ee TSP iyo matoorrada TSPR. Xarig ku habboon furitaanka safka.

√ Hoose oo jilicsan - bir bir ah ama polyurethane ee TSP; Snastap-on Snastomer ee Tirtomer ee TSPR.

√ tuubada ka daadashada - bir ee TSP; Elastomer wuxuu daboolay TSPR. Dhammaan qaybaha birta qoyan gebi ahaanba miridhku way galeen.

√ Bixinta gacanta oo hooseysa - midna

√ Caddaynta - Nidaamka xidhiidhka qalabka oo dibedda ah ayaa lagu rakibi karaa matoorka sidii ikhtiyaar. Bedel ahaan, qalabka mashiinka mashiinka ah wuxuu ku habboon yahay shaashad dheer oo ka soo baxa isha hunguriga.

√ Qalabka - Bambooyinka waxaa lagu soo saari karaa qalab adag oo loo istcimaalo.

TSPR caagga caagga ahBamka jilicsan oo jilicsancabirrada waxqabadka

| Nooc | Max.Power P (kW) | Waxqabadka biyaha cad cad | Qurxinta dia. (mm) | ||||

| Awoodda q | Madaxa h (m) | Xawaare n (r / min) | Max. Eff. (%) | ||||

| m3 / h | l / s | ||||||

| 40pv-tsspr | 15 | 17.28-39.6 | 4.8-11 | 4-26 | 1000-2200 | 40 | 188 |

| 65QV-TSPR | 30 | 22.5-105 | 6.25-29.15 | 5.5-30.5 | 700-1500 | 51 | 280 |

| 100rv-tsspr | 75 | 64.8-285 | 18-79.2 | 7.5-36 | 600-1200 | 62 | 370 |

| 150sv-tsspr | 110 | 108-479.16 | 30-133.1 | 8.5-40 | 500-1000 | 52 | 450 |

| 200sv-tsspr | 110 | 189-891 | 152.5-247.5 | 6.5-37 | 400-850 | 64 | 520 |

| 250tv-tsspr | 200 | 261-1089 | 72.5-302.5 | 7.5-33.5 | 400-750 | 60 | 575 |

| 300tv-tsspr | 200 | 288-1267 | 80-352 | 6.5-33 | 350-700 | 50 | 610 |

Codsiyada batoonka tooska ah ee TSPR

TSPR iyo Sppr waxay naqshadeeyaan, oo lagu soo saaray cabirro mitir caan ah, oo ah mid sahlan oo ah bambooyinka 'sumculs', diyaarinta dhuxusha, ee loo yaqaan 'sturry', oo ah kiimiko iyo dhaando firfircoon, iyo ku dhawaad haanta kale, goynta kale, godka kale. Xaaladda wax looga qabanayo-ee-dhulka-slurry-ka-slurry.

Xusuusin:

Bambaanooyinka jilicsan ee jilicsan ee TSPRE-ga Sleurry iyo Spades ayaa kaliya isweydaarsan kara oo lagu safan kara bustaha jilicsan ee diiran ee loo yaqaan 'versical' iyo spares.

Qalabka mashiinka ah, stripntal, ashyaa'da sleurry sleurry sleurry:

| Koodhka sheyga | Sharraxaadda Aaladda | Qaybaha dalabka |

| A05 | 23% -30% CR CR Cad | Impeller, saqaf, jarista, giraanta, giraanta dhaanta, sanduuqa walxaha, xagaalka, xarkaha xarkaha xarkaha |

| A07 | 14% -18% CR Cad cad | Impeller, xirmooyin |

| A49 | 27% -29% CR CR CARNBON Cadho Hubbon | Impeller, xirmooyin |

| A33 | 33% CR NEROSIMS & CADAALADA CADAALADAHA CADAALADA | Impeller, xirmooyin |

| R55 | Caag dabiici ah | Impeller, xirmooyin |

| R33 | Caag dabiici ah | Impeller, xirmooyin |

| R26 | Caag dabiici ah | Impeller, xirmooyin |

| R08 | Caag dabiici ah | Impeller, xirmooyin |

| U01 | Polyurethane | Impeller, xirmooyin |

| G01 | Bir bir ah | Saxanka jir, daboolo saxan, weel, giraan bixiye, oo dhagxista guriga, saldhigga |

| D21 | Birta Dheek | Saxanka jir, daboolka daboolka, adoo dhalaya guriga, saldhigga |

| E05 | Kaarboon | Kabaalo gaari-faras |

| C21 | Bir bir ah, 4cr13 | Shaft Sleve, giraanta galmada, khafiifinta land, giraan qoorta, qanjirka qanjirka |

| C22 | Bir bir ah, 304s | Shaft Sleve, giraanta galmada, khafiifinta land, giraan qoorta, qanjirka qanjirka |

| C23 | Birta aan caadiga ahayn, 316ss | Shaft Sleve, giraanta galmada, khafiifinta land, giraan qoorta, qanjirka qanjirka |

| S21 | Lowyll caaro | Ringyada wadajirka ah, shaabadaha wadajirka ah |

| S01 | Lowska epdm | Ringyada wadajirka ah, shaabadaha wadajirka ah |

| S10 | Nitrile | Ringyada wadajirka ah, shaabadaha wadajirka ah |

| S31 | Nafis | Impeller, saqaf, giraanta engega, ka-leexashada, fargalinta wadajirka ah, eedaha wadajirka ah, shaabadaha wadajirka ah |

| S44 / K S42 | Neaoprene | Impeller, saqafyo, siddooyin wada jir ah, xargaha wadajirka ah |

| S50 | Tro | Ringyada wadajirka ah, shaabadaha wadajirka ah |